Automatic palletizers can be low level palletizers, which load packaged units from a floor level, or they can be high level palletizers, which move packaged units from another story above. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing...

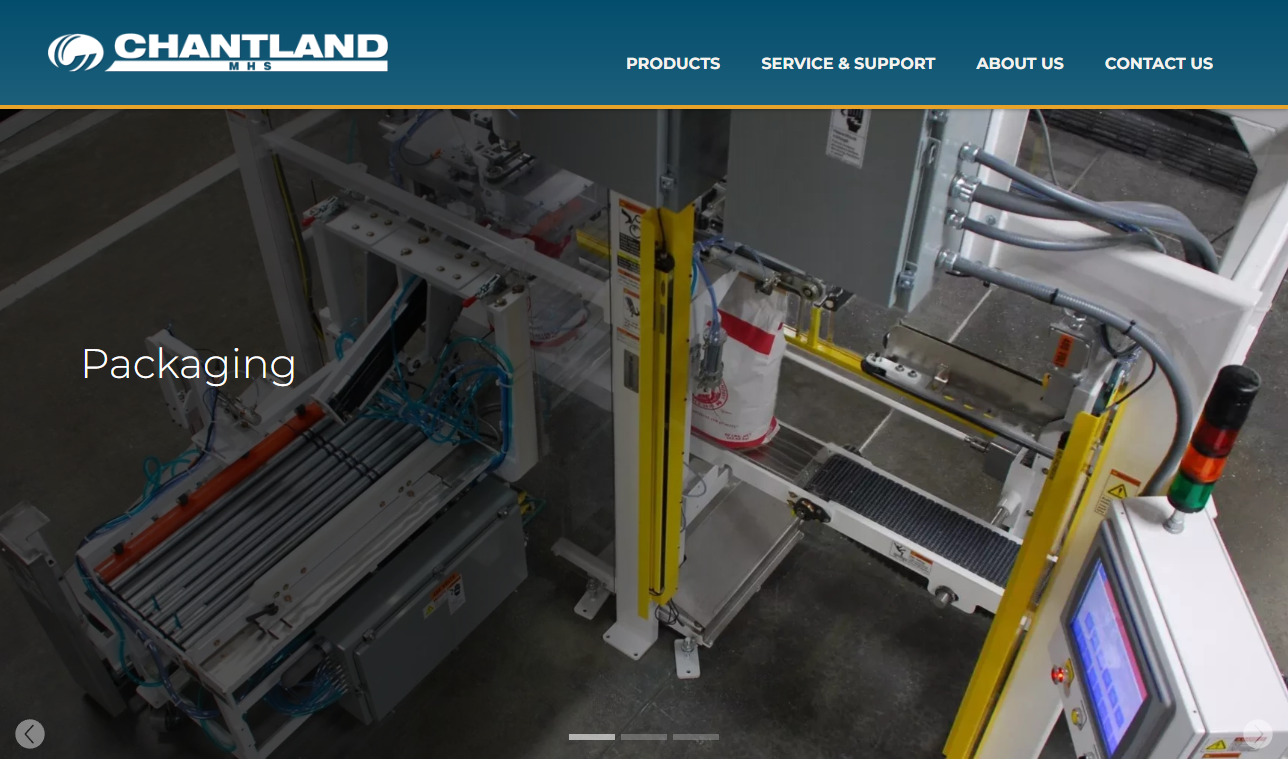

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

More Palletizing Machine Manufacturers

Palletizing machines may be designed to handle one type of product, such as bag palletizers, case pickers, drum palletizers and bottle palletizers, or they may handle several different types of packages.

Distribution centers and manufacturing facilities handling incoming shipments often use depalletizers to unload packaged units, and palletizing machine accessories such as pallet dispensers and load transfer stations are used to assist in managing both pallets and loads.,/p>

Palletizing machines can be fully automatic or semi-automatic and are typically powered through hydraulic, pneumatic or electro-mechanical means. Three of the most common types of palletizing machines include robotic palletizers, low level palletizers and high level palletizers.

Fully automatic, robotic palletizing machines are typically stationed between a conveyor line of incoming product units and a pallet dispenser. A hydraulic robotic arm lifts cases, bottles, bags or drums using flat pincer arms or suction cup arms in organized rows onto a pallet, stacking units with near-perfect precision.

Robotic palletizing machines may be altered to work with different types of product units and are excellent for handling fragile or heavy product units, although they may be slower, as they can only place one unit or row at a time. Low level and high level palletizing machines are two types of conveyorized palletizing machines that have a feed area that receives the goods intended for palletization.

In low level palletizing machines, or floor-entry palletizing machines, products are loaded from the ground level, while high level palletizers are loaded from above or from the story above. The packaged units are received by roller conveyors and are continuously transferred and sorted to the pallets by automated conveyor rollers, allowing greater packaging speed than robotic palletizers.

Low and high level palletizing machines may be fully automatic, requiring no manual involvement, or they may be semi automatic, requiring loads to be manually connected and disconnected from the palletizer lifting arm.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

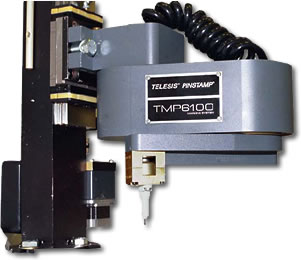

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

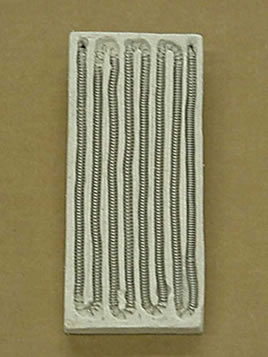

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches