Some benefits of load transfer stations include eliminating injuries to the worker that are associated with heavy lifting and repetitive-motion, improving process and plant cleanliness and reducing costs. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing...

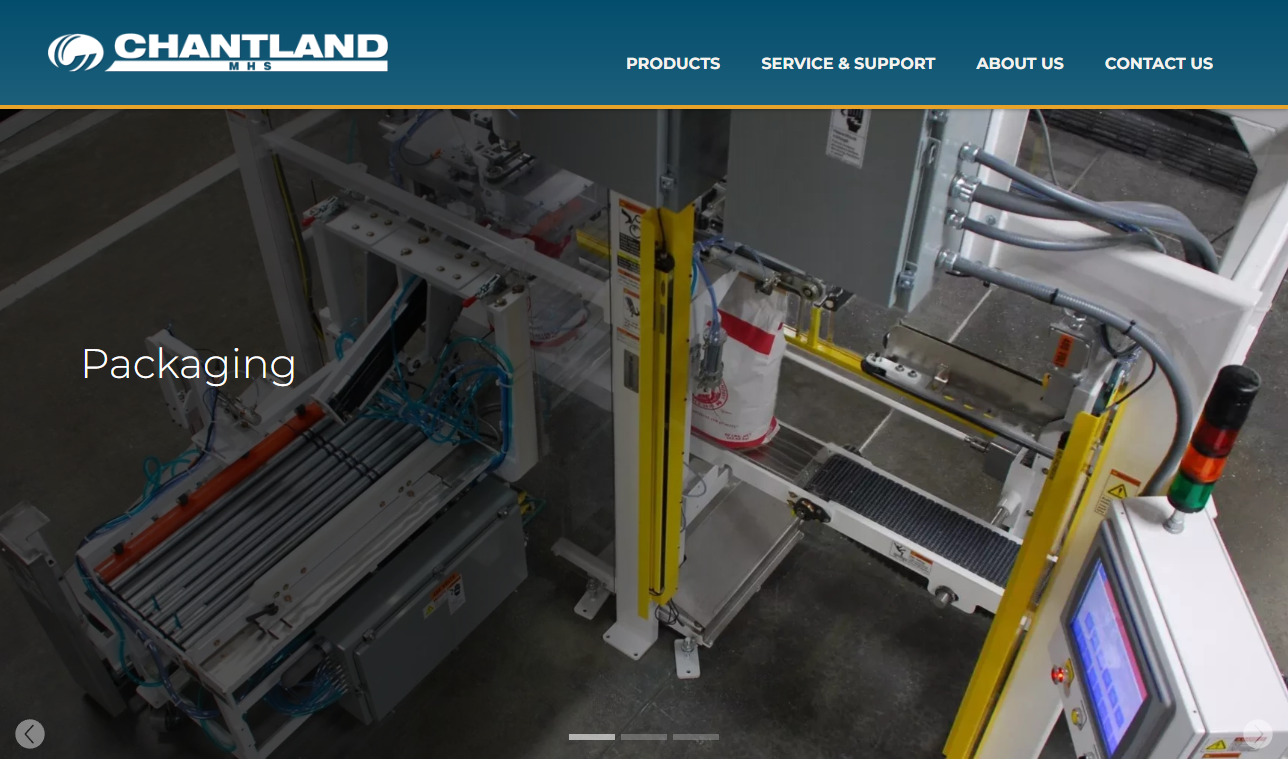

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

More Load Transfer Station Manufacturers

Load transfer stations are often utilized in industries such as food processing, warehousing, beverage, pharmaceutical, electronics, packaging, commercial, agricultural, cosmetics and medical.

Typically used in manufacturing environments that require rapid pallet throughput, load transfer stations maintain critical work flow as well as helping to keep the warehouse floor space free of obstacles. Used for dispensing, collecting and accumulating loads of cases, bottles, glass vials, pails, combo boxes, bags or drums, load transfer systems are particularly useful for companies with a high pallet usage.

As a cost-effective alternative to load inverters, pallet transfer systems offer simple pallet transfer between pallet types and other load bases.

The basic design of a load transfer station is typically operated by a fork lift driver and can be accessed from two sides for loading, or three sides for unloading. Even is this basic form, a load transfer station can offer extreme flexibility in terms of the number of type of processes that it can perform.

However, in more complex pallet transfer system designs a pallet dispenser, a lift mechanism and an output roller conveyor can be added to the basic design for a fully automated load transfer system.

A pallet dispenser is a device that is used to feed or dispense empty pallets to conveyors in larger palletizing systems or automatic palletizers. A roller conveyor is a type of material handling equipment that moves loads from one load base to another while using rollers that are placed parallel to one another to provide movement.

A lift mechanism that a load transfer system could use would be a mechanical arm or an elevator plate that would raise the load up and away from the load base. An example of one method of pallet transfer would be when the load transfer station's lift mechanism raises the load from the pallet, leaving room for the old pallet to be pushed away and a new pallet to be put in its place. Once the new pallet is in the place, the lifting mechanism will position the load onto the new pallet.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

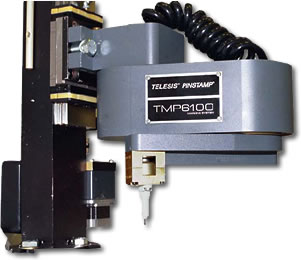

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches