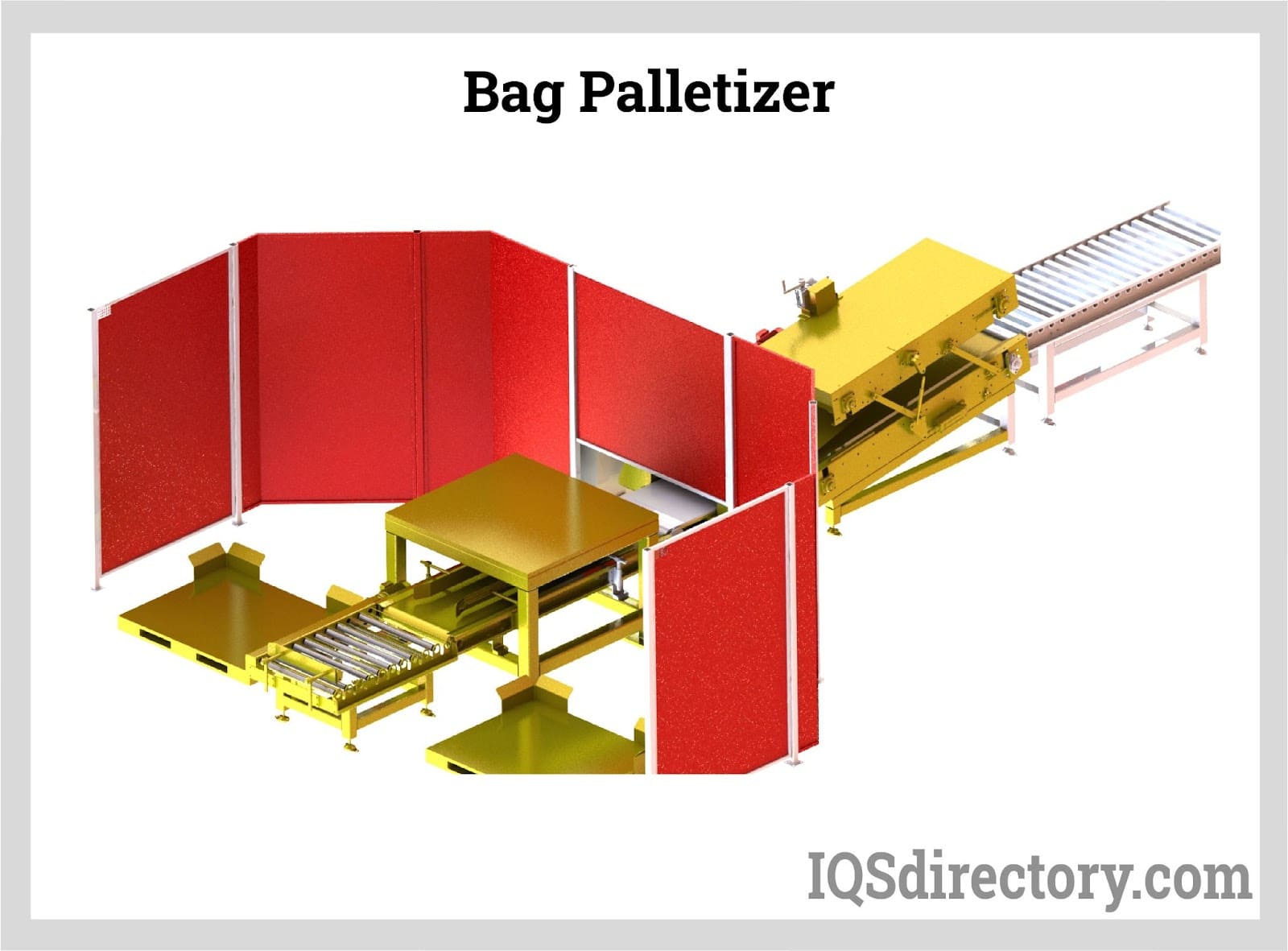

A bag palletizer is a versatile machine that can handle a wide range of variations in bag dimensions to help produce square, secure pallet loads. Installation and operation do not involve using stairs or platforms, and all palletizing tasks and maintenance points are easily situated at floor level. They are all designed to stack boxes or bags on a pallet so they can be carried, either with robotics or conventionally. Although it first appears straightforward, several criteria ultimately determine the kind of equipment you should employ. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing...

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

More Bag Palletizer Manufacturers

These devices traditionally required a lot of manual labor to operate and had very few uses. Today, these machines can now do much more than just stack bags and boxes on top of one another because of their wide-ranging settings and automation. Certain bag palletizers can lift and move things in addition to bags. For instance, palletizers are frequently used to lay a baseboard or other material above the surface of the pallet to give grip or cushioning before the pallet is loaded with bags. Bag palletizers might be pricey initially, but long-term productivity advantages and the absence of worker injury frequently make up for the cost.

Factors to Consider When Selecting Bag Palletizers

- How quickly can a pallet be completed with one system versus another?

- How much weight can a palletizer handle? What is the weight of the items you are commonly loading?

- How do available different manufacturers ‘stack up’ against each other in terms of their reliability? Are replacement parts and service readily available if needed? Are repairs something you can do in-house with the system chosen? Or, is outside assistance going to be required? What is the downtime going to be in those instances when repair may be needed?

- What is the initial cost versus the long-term benefit considering the aforementioned, and other possible, factors?

Modern Bag Palletizer Features and Specifications

- Conveyor with roller infeed

- Bag-orienting, pop-up rotating device

- Non-contact sensors to keep tabs on machine performance

- Counterweight elevator tables that eliminate drive motor stress

- Layer retainer bar adjustability

- Variable frequency drives for motors

- Preparation equipment based on daily shift, or batch, operations

- Non-contact sensors with quick disconnect and LED indications

- Easy steps for either manual or automatic functions

- Sealed bearings

- A touchscreen to help set configuration changes, check diagnostics, perform machine jogging, or assist with troubleshooting

- A screen-based bag counter

- Options for automatic or manual pallet handling and dispensing

Construction of Bag Palletizers

- Bag palletizer designs come in various forms to accommodate the various manufacturing and distribution situations found throughout various industries.

- Almost all bag palletizers are fully automated and able to run for lengthy periods, essentially unattended.

- Bag palletizers employ equipment and technology similar to other palletizing devices.

Working of Bag Palletizers

- The bag palletizer regulates the picking up and depositing of the bag onto the pallet.

- By using this specific manipulation and placement approach, pallets are produced that are extremely compact and flawlessly stacked, improving manufacturing quality.

- The pallet serves as a basis for the materials and products, facilitating effective handling, storage, and transportation of the unit load, which is the combination of the materials and base of the pallet plus the goods.

- To make a "bag," layers of various objects are stacked on a wooden platform pallet then wrapped.

- The pallet gives each unit a sturdy and load-bearing bottom so it may be moved and loaded easily using a pallet jack, forklift, crane, or other handling equipment.

Benefits of Bag Palletizers

- The problem of transporting, stacking, and storing vast amounts of bagged goods can be solved with bag palletizers.

- Palletizing equipment lessens the likelihood of worker injuries brought on by strain. Instead, they provide safe and effective material handling when built and used correctly.

- Thanks to their modular architecture, bag-palletizer systems are simple to move, set up, and integrate into existing packaging processes.

- Some bag palletizers can raise many layers of bags with a single arm motion, which can significantly boost productivity and operating efficiency.

- They are installed easily, leaving only a small footprint on operations.

- They are easily machine-guarded with easy access and good visibility.

- Bags are gently handled when being placed, oriented, or moved.

Applications of Bag Palletizers

- If the weight of large bags of granular materials, such as sugar or cement, is not evenly distributed when hoisted, the bags may lose their form or even burst. Bag palletizers may swiftly and properly lift such materials without danger of product loss due to bag punctures or other issues.

- They are also highly helpful for stacking and manipulating items that can distort if handled incorrectly.

- Many bag palletizers may also serve as depalletizers, inserting and extracting items.

- Semi-automatic palletizing helps a firm decrease liability and boost output.

- Palletizers can place potentially-dangerous goods in a container or bag onto a pallet before transportation in agricultural, food-processing, pharmaceutical, and chemical-engineering settings, thereby limiting risks to workers.

- High-speed bag palletizing is available for quickly storing and shipping items.

Choosing the Right Bag Palletizer Manufacturer

To ensure the most positive outcome when purchasing a bag palletizer from a bag palletizer manufacturer, it is important to compare several companies using our directory of bag palletizer manufacturers. Each bag palletizer manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each bag palletizer business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple bag palletizer companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches