Case palletizers are used to lift items from production lines and place or stack them perfectly onto a pallet for shipping, moving, or storing. The items can be stacked in different configurations like column-stacked, interlocked or pin-wheel configurations. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing...

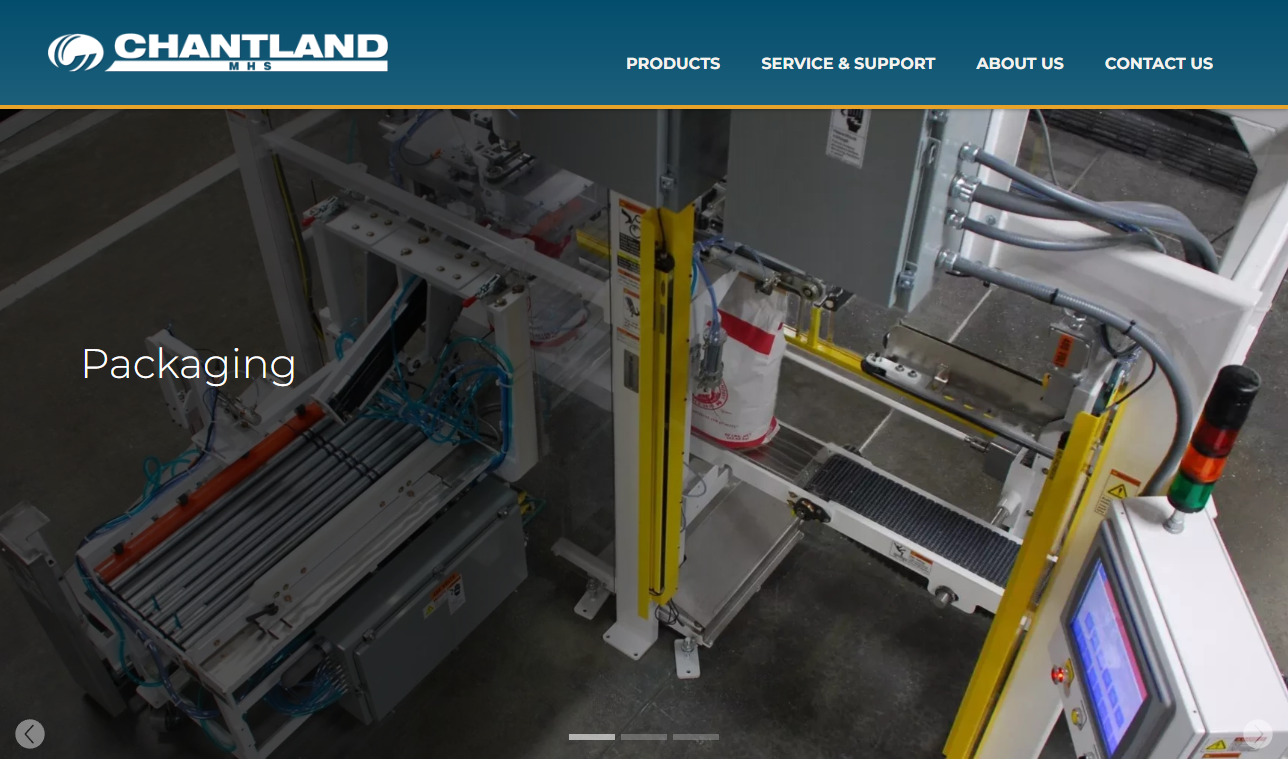

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

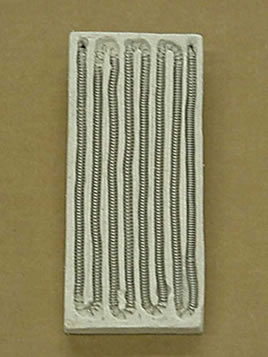

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

More Case Palletizer Manufacturers

Automatic palletizers of this variety allow complex palletizing routines to be completed without the need for multiple handling operations, and do not require a lot of manual labor or human supervision.

These palletizers are developed to help manufacturers reallocate labor to tasks in less harmful environments, meet aggressive production requirements and save production area floor space. The design incorporates zero pressure, non-contact accumulation roller conveyors to gently position cases prior to palletizing.

There are several methods that are used to customize the case palletizers to the needs of the manufacturing facility in which it is to be used. These customizable features can include HMI panels and data software options.

Case palletizing systems provide increased line efficiency, increased production, improved quality of finished units, greater line flexibility, reduction in labor injuries, and reduction in staffing requirements.

Case palletizers come either as high level or low level palletizers. High level palletizers are machines that have an infeed elevation higher than the floor or ground level, usually about 100" to 144" higher. Advantages of high level palletizers include a higher throughput relative to size of the footprint, high speed applications above 40 or 50 cases per minute and a higher footprint than some low level palletizers.

Low level palletizers (also known as floor level palletizers) usually have an entry level of about 30" to 36". Advantages of the low level palletizers include being generally lower in cost and do not require a work platform. The maintenance for a floor palletizer is easier than a high level palletizer because the parts are easier to access. Lastly, the infeed elevation makes the low level palletizer ideal for close coupling to the case packers and case sealers.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

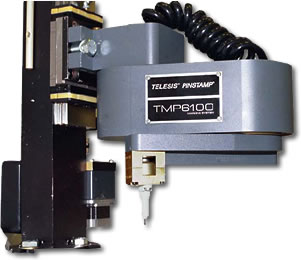

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches