When a customer has made the decision to purchase, their part of the transaction ends and a new process begins. Regardless of what is being purchased from small electronic items to large pieces of machinery, it has to be found in a storage system and prepared for delivery. In the warehousing industry, this is referred to as picking or case picking. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing...

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

More Case Picking Manufacturers

The process of case picking, as easy as it may sound, is actually very technical and requires pickers that are sharp enough to understand organization and proper picking procedures. Though it may seem that all that has to happen is walk to a shelf and take and item off the shelf, there is far more to the process. If you have ever visited a large warehouse, you can get an idea of how complex the process can be.

What is Case Picking?

Case picking refers to picking cases, cartons, containers, or boxes from a highly organized and computerized storage facility. This type of process is generally a part of retail operations, small industrial equipment such as copiers, and, most recently, as part of ecommerce operations. Case picking is a part of logistics systems and the supply chain, which is one of the most critical aspects of product turnover.

The picking process begins with an order that is delivered via computer, though there are some retail operations that still use paper requisitions. In most warehouses, the timing of the case picking process begins with the receipt and acceptance of the order. This activates a response from the case picking specialist who will send the order on to the area where the product can be picked.

Case Picking Warehouse Organization

A key factor in case picking is the layout of the warehouse. For most operations, frequently picked items are located close to the shipping point and are continually kept in quantities to meet the need. Other operations group products numerically by part number or alphabetically by part description, a system that may not be the most efficient since it does not account for product turnover.

Once the item is found and picked, there are several types of methods of getting it to the shipping location. Though it may be assumed that it would be carried by the person who picked it, that method is outmoded and very seldom used. There are a wide variety of transport methods for moving picked items to shipping, which include conveyors, forklifts, or various forms of automation.

Case Picking Methods

The function of a warehouse may be envisioned as a simple matter of organizing a group of items for shipping, much like someone would organize their basement or garage. There is far more to the process than simply placing items where they can be conveniently picked and shipped. Unlike organizing items around the house, warehousing requires several technological elements to ensure proper control of inventory. A part of the process is the method of picking being used.

There are several different types of picking methods each of which has been designed to fit the warehousing architecture and process. Four of the common methods are basic, batch, zone, and wave. Each of these methods has been incorporated into warehousing and product shipping.

As the name basic implies, with basic case picking, warehouse inventory is stored in a static pallet rack system. Orders are picked one at a time following the most efficient and productive route. The organization of the picking process has a beginning point and ends at the packing and shipping location.

In the batch picking process, also known as multi order picking, orders are grouped together into manageable batches. A pick list is used as the guide for the order picker to collect the items in the batch. A cart with several shelves or a forklift is used with pallets to separate each part of the order.

The zone picking method is a very common form of picking for large operations. Each part of the warehouse is assigned to a picker who is responsible for placing items, ensuring that there is a sufficient amount on hand, and picking orders. When items are required from multiple zones, they are picked in the order of the zone locations.

A combination of zone and batch picking is wave picking where an order for several items is picked from all zones at the same time to be consolidated for a single picker. The wave method has the shortest cycle time and provides the fastest service. It is the predominantly used method for large warehousing operations.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

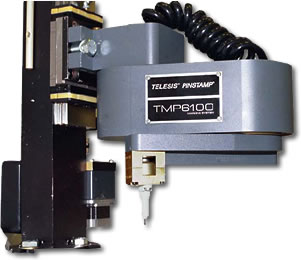

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

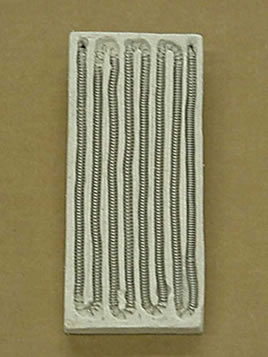

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches