Kinesys Automation, Inc.

Kinesys Automation, Inc.Request A Quote

Oakland, NJ | 201-337-5000https://kinesysautomation.com/

Kinesys Automation, Inc. is a leading provider of innovative automation solutions for the manufacturing industry. Founded in 1976, the company has over four decades of experience in delivering cutting-edge technology to help clients optimize their production processes and maximize efficiency. Headquartered in Oakland, New Jersey, Kinesys Automation has a strong presence in the United States, with additional locations in Canada and Mexico. One of Kinesys Automation's core product offerings is their palletizers. Palletizers are automated systems that arrange products on pallets for transport or storage. These systems can handle a wide range of products, including bags, boxes, and containers of varying sizes and weights. Kinesys Automation's palletizers are designed to meet the unique needs of each client, with custom configurations that can accommodate specific product dimensions, throughput requirements, and production environments. Kinesys Automation's palletizers are highly versatile, offering a range of capabilities to help clients streamline their production processes. These capabilities include: 1.High-speed throughput: Kinesys Automation's palletizers can handle a high volume of products, with speeds of up to 200 units per minute. 2.Flexibility: The palletizers can accommodate a variety of product types and sizes, allowing clients to optimize their production processes. 3.Precision: The systems are designed to ensure precise placement of products on pallets, reducing waste and maximizing storage and transport efficiency. 4.Safety: Kinesys Automation's palletizers feature advanced safety features, including sensors and interlocks, to protect workers and prevent accidents. In addition to their palletizer products, Kinesys Automation also offers a range of services to support their clients. These services include: 1.Engineering and design: Kinesys Automation's team of experts can help clients design and engineer custom automation solutions to meet their specific needs. 2.Installation and commissioning: The company's experienced technicians can install and commission the automation systems, ensuring they operate smoothly and efficiently. 3.Training and support: Kinesys Automation provides training and ongoing support to help clients maximize the benefits of their automation solutions. 4.Maintenance and repair: The company offers maintenance and repair services to keep the automation systems operating at peak performance and minimize downtime. Overall, Kinesys Automation Inc.'s palletizers and services provide clients with a comprehensive solution for optimizing their production processes. With their focus on customization, precision, and safety, Kinesys Automation, Inc. is well-positioned to meet the evolving needs of the manufacturing industry.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

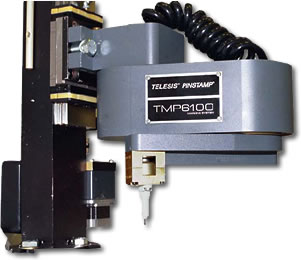

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches