Palletizing systems can be used to load and unload all kinds of materials from pallets in all kinds of circumstances. Bag palletizers are used specifically to place bags on pallets in advance of shipment or storage or to remove them after receipt of a shipment. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing...

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

More Palletizing Equipment Manufacturers

Bulk quantities of cement and other heavy granular materials are often moved by bag palletizers. Drum palletizers accomplish the same task as bag palletizers, except instead of bags they move drums.

Chemical processors and other operations that deal with large quantities of drums can benefit greatly from the use of drum palletizers; they can load drums more quickly and safely than human employees can. In addition to boosting productivity, palletizing machines improve workplace safety by reducing the amount of strenuous lifting for employees. Palletizing equipment can lift and move very large quantities of materials without becoming fatigued or injured.

Articulated arm palletizers, automatic palletizers, gantry palletizers, in-line palletizer systems, manual palletizers, robotic palletizers, row stripper palletizers, selective compliant articulated robot arm (SCARA) palletizers, semi-automatic palletizers and vacuum-head unit palletizers are just a few of the palletizer equipment varieties available to industrial operations.

Palletizing equipment is divided into three main categories: low-level palletizing equipment, high-level palletizing equipment, and robotic palletizing equipment, all of which differ based on the location of their feed area.

While low-level palletizing equipment is fed from the ground, high-level palletizing equipment is fed through a hopper overhead. With the use of either type of palletizing equipment, the feed is received in a rolling fashion and is continuously transferred to the pallets. Robotic palletizers, in contrast, do not utilize a feeding area.

Instead, they consist of an arm that individually picks up and places each item on the pallet, reducing the risk of damage to the product and injury to the workers. Depending on individual palletizing equipment needs, many options of palletizing equipment are available.

In addition to various speeds, capacities, feeding methods, and sizes, palletizing equipment can be tailored to meet a wide range of stack patterns, types of slip sheet, and wrapping configurations.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

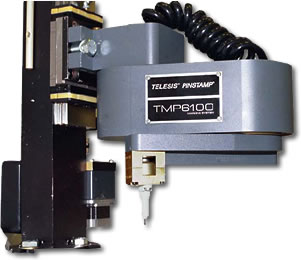

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches