Pallet conveyors are an essential component of modern manufacturing, distribution, and warehouse facilities. Pallet conveyors are a type of conveyor system that uses pallets as a base for transporting goods or products. They provide a reliable and efficient method for transporting heavy loads of materials, goods, and products from one point to another. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing...

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

More Pallet Conveyor Manufacturers

Common Components of Pallet Conveyors

All pallet conveyors have some common components, including the conveyor bed, rollers or chains, a drive mechanism, sensors, and a control system. The conveyor bed is the base structure of the conveyor system and supports the pallets. Rollers or chains provide the movement of the pallets along the conveyor bed, while the drive mechanism powers the conveyor. Sensors are used to detect the presence of the pallets and control their movement, and the control system manages the entire conveyor system.

Variations of Pallet Conveyors

There are various types of pallet conveyors available, each designed for specific applications. Some common design variations include belt conveyors, chain conveyors, roller conveyors, gravity conveyors, and automated guided vehicles (AGVs). Belt conveyors use a continuous belt to move the pallets, while chain conveyors use chains to move them. Roller conveyors use rollers to move the pallets along, while gravity conveyors rely on the force of gravity to move the pallets. AGVs are self-guided mobile robots that transport the pallets automatically.

Considerations Regarding Pallet Conveyors

While pallet conveyors offer many benefits, they also have some limitations to consider. The initial investment cost can be high, and they require a significant amount of space. Additionally, pallet conveyors have limited flexibility, making them less adaptable to changes in production processes.

Benefits of Pallet Conveyors

Despite their limitations, pallet conveyors offer several benefits. They increase efficiency by reducing the time required for transportation and loading and unloading processes. They improve safety by reducing the risk of injury associated with manual handling of heavy loads. Pallet conveyors also reduce labor costs by eliminating the need for manual transportation and handling.

Applications of Pallet Conveyors

There are numerous applications for pallet conveyors. We examine some of their more popular applications below.

Assembly Lines

Pallet conveyors are commonly used in assembly lines to transport goods between workstations. The conveyors can be configured to stop and start automatically, making it easier to coordinate the work of multiple workers. Additionally, pallet conveyors can be equipped with sensors to detect the presence of products on the pallet, ensuring that the assembly line runs smoothly without any delays.

Manufacturing Facilities

Pallet conveyors are commonly used in manufacturing facilities to transport raw materials and finished products between different stages of production. Pallet conveyors can be used to move heavy and bulky items, such as engines, transmissions, and large machine parts. They can also be used to move smaller items, such as electronics components.

Food Processing

Pallet conveyors are often used in the food processing industry to transport food products between processing stations. In this application, pallet conveyors are typically made of stainless steel or other materials that can withstand harsh cleaning chemicals and high temperatures. They are also designed to prevent contamination and meet strict hygiene standards.

Warehousing

Pallet conveyors are used in warehousing to transport goods between storage areas and shipping docks. They can be used to move products from one area of the warehouse to another, as well as to load and unload trucks. In this application, pallet conveyors can be equipped with RFID tags or other types of sensors to help track inventory and ensure that products are moved to the correct location.

Pharmaceutical Manufacturing

Pallet conveyors are used in pharmaceutical manufacturing to transport medications and other products between different stages of production. In this application, pallet conveyors are designed to prevent contamination and meet strict hygiene standards.

Automotive Manufacturing

Pallet conveyors are used in automotive manufacturing to transport large and heavy parts between different stages of production. They can also be used to move smaller parts, such as electronics components.

E-Commerce Fulfillment Centers

Pallet conveyors are used in e-commerce fulfillment centers to transport products between storage areas and shipping docks. They can be used to move products from one area of the fulfillment center to another, as well as to load and unload trucks.

Airport Baggage Handling

Pallet conveyors are used in airport baggage handling systems to transport luggage between check-in counters, baggage sorting areas, and airplanes. In this application, pallet conveyors are designed to handle a wide range of luggage sizes and shapes, and can be equipped with barcode scanners and other types of sensors to help track luggage.

Building Materials Industry

Pallet conveyors are used in the building materials industry to transport heavy items such as bricks, blocks, and lumber between different stages of production. They can also be used to transport smaller items, such as roofing tiles and insulation.

Choosing the Correct Pallet Conveyor Manufacturer

To ensure you have the most beneficial outcome when purchasing a pallet conveyor from a pallet conveyor manufacturer, it is important to compare several companies using our directory of pallet conveyor manufacturers. Each pallet conveyor manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each pallet conveyor business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple pallet conveyor companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

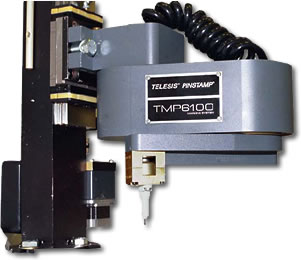

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

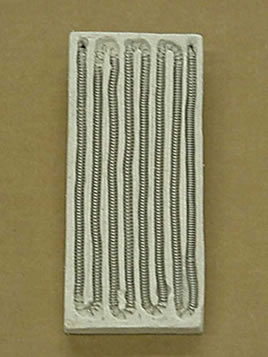

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches